LVL timber formwork, also known as laminated veneer lumber formwork, is a popular and efficient construction material used in various building projects. It offers several advantages over traditional formwork materials, making it a preferred choice for many architects, engineers, and contractors. In this article, we will delve into the benefits of using LVL timber formwork, its applications in different construction projects, safety considerations, and the future of this innovative construction material.

Understanding LVL Timber Formwork

Definition and Manufacturing Process of LVL Timber

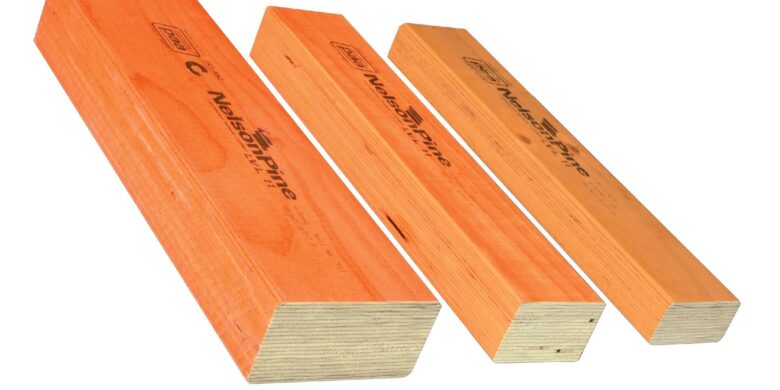

LVL timber is a type of plywood made by bonding thin layers of wood veneers together using adhesive and heat. This manufacturing process results in a strong, durable, and dimensionally stable construction material. LVL timber formwork is specifically designed for use in concrete construction projects, offering exceptional strength and stability required for supporting the weight of wet concrete.

When it comes to the manufacturing process of lvl timber formwork, it is important to note that the wood veneers used are carefully selected to ensure uniformity in strength and quality. These veneers are then layered and bonded together under high pressure, creating a solid and reliable material that is free from knots, voids, or other imperfections commonly found in traditional timber.

Key Features of LVL Timber Formwork

One of the key features of LVL timber formwork is its superior strength-to-weight ratio. Thanks to the laminated construction, LVL timber formwork can withstand heavy loads and provide reliable support during concrete pouring. Additionally, this type of formwork is resistant to warping and shrinkage, ensuring accuracy and precision in concrete shaping.

Moreover, the smooth surface of LVL timber formwork allows for easy stripping after the concrete has set, reducing the time and effort required for formwork removal. This not only increases efficiency on the construction site but also minimizes the risk of surface blemishes on the finished concrete structure.

Another advantage of LVL timber formwork is its versatility. It can be easily cut, shaped, and combined to form customized formwork systems, catering to the unique requirements of each project. This flexibility allows architects and contractors to design and build complex geometries without compromising on structural integrity.

Advantages of Using LVL Timber Formwork

Durability and Strength of LVL Timber

One of the primary advantages of using LVL timber formwork is its exceptional durability and strength. Unlike traditional timber formwork, LVL timber can withstand the pressures exerted by wet concrete without warping or deforming. This durability ensures that the formwork retains its shape and integrity throughout the construction process, resulting in high-quality concrete structures.

Furthermore, LVL (Laminated Veneer Lumber) timber is engineered to be stronger and more uniform than traditional timber, providing consistent performance on construction sites. Its high strength-to-weight ratio makes it an ideal choice for formwork applications where heavy loads need to be supported without compromising structural integrity.

Environmental Benefits of LVL Timber

In addition to its robustness, LVL timber formwork offers environmental benefits. It is a sustainable construction material, as it is made from fast-growing plantation timber, reducing the reliance on slow-growing hardwoods. LVL timber formwork also has a lower carbon footprint compared to other formwork materials, contributing to a more sustainable and eco-friendly construction industry.

Moreover, the manufacturing process of LVL timber involves using adhesives that are formaldehyde-free, ensuring minimal impact on indoor air quality. This eco-friendly feature makes LVL timber a preferred choice for green building projects aiming to achieve LEED (Leadership in Energy and Environmental Design) certification.

Cost-Effectiveness of LVL Timber Formwork

Another advantage of LVL timber formwork is its cost-effectiveness. While the initial cost of LVL timber formwork may be slightly higher than traditional timber formwork, the long-term savings outweigh the initial investment. LVL timber formwork is reusable and can withstand multiple concrete pours, reducing the need for frequent replacement. Additionally, its dimensional stability minimizes the need for excessive bracing and support, resulting in faster and more cost-efficient construction processes.

Furthermore, the smooth surface of LVL timber formwork requires minimal finishing, saving both time and labor costs during the construction phase. Its ability to resist warping and twisting reduces material waste, making it a sustainable and economical choice for formwork applications in the construction industry.

Applications of LVL Timber Formwork

Residential Construction

LVL timber formwork is widely used in residential construction projects. Its strength and versatility make it suitable for forming foundation walls, columns, beams, and slabs in houses and apartment buildings. The ability to create complex geometries with ease makes LVL timber formwork ideal for constructing unique and architecturally appealing residential structures. Read more about geometries at https://scgp.stonybrook.edu/archives/29958

Moreover, LVL timber formwork offers the advantage of being lightweight compared to traditional formwork materials, making it easier to handle and install on residential construction sites. This lightweight nature not only enhances the efficiency of the construction process but also reduces labor costs, making it a cost-effective solution for builders and developers.

Commercial Construction

In commercial construction, LVL timber formwork finds applications in various building elements such as walls, floors, and staircases. Its load-bearing capacity and dimensional stability make it a reliable choice for constructing commercial buildings, ensuring the safety and structural integrity of the structure.

Additionally, the smooth surface finish achieved with LVL timber formwork allows for minimal surface treatment requirements, saving time and resources during the construction of commercial properties. This smooth finish also provides a polished look to the final structure, enhancing its aesthetic appeal and market value.

Infrastructure Development

For infrastructure development projects such as bridges, tunnels, and dams, LVL timber formwork proves to be a valuable construction material. Its strength and durability allow it to withstand the heavy loads and pressures associated with these large-scale projects, ensuring long-lasting and reliable structures.

Furthermore, the dimensional stability of LVL timber formwork makes it particularly well-suited for infrastructure projects where precision and accuracy are crucial. This stability ensures that the formwork maintains its shape and dimensions under varying environmental conditions, guaranteeing the structural integrity of the infrastructure being built.

Safety Considerations for LVL Timber Formwork

When it comes to handling and storing LVL timber formwork, safety should always be the top priority. While the material offers numerous advantages such as durability and versatility, it is crucial to follow specific guidelines to ensure the safety of workers and the integrity of the formwork. Proper lifting techniques, including using lifting equipment when necessary, can prevent injuries and accidents. Additionally, storing the formwork in a dry and secure location helps maintain its structural integrity and prolong its lifespan.

Handling and Storage Guidelines

While LVL timber formwork offers numerous advantages, it is essential to prioritize safety during handling and storage. Proper lifting techniques, using appropriate equipment, and storing the formwork in a dry and secure location are crucial to prevent accidents and maintain its integrity.

Furthermore, it is recommended to inspect the formwork before and after each use to check for any signs of damage or wear. Any compromised pieces should be repaired or replaced immediately to avoid safety hazards on the construction site. By following these guidelines, workers can ensure a safe working environment and the longevity of the LVL timber formwork.

On-Site Safety Measures

On-site safety measures are equally important when working with LVL timber formwork. Ensuring proper bracing, leveling, and securing the formwork during concrete pouring minimizes the risk of structural failure and ensures the safety of workers and the project as a whole. Regular inspections and maintenance of the formwork are also essential to identify any signs of wear or damage that may compromise its performance. To know more about pouring click here.

Moreover, providing adequate training to workers on the proper assembly and dismantling of the formwork can significantly reduce the likelihood of accidents. By promoting a culture of safety and adherence to guidelines, construction teams can mitigate risks and create a secure working environment for all involved.

Future of LVL Timber Formwork

Technological Advancements and Innovations

The future of LVL timber formwork looks promising with ongoing technological advancements and innovations. Researchers and manufacturers are constantly exploring ways to enhance the material’s strength, stability, and sustainability. New adhesive technologies, advanced production techniques, and even the integration of digital design tools are pushing the boundaries of what LVL timber formwork can achieve.

One exciting technological advancement in the field of LVL timber formwork is the development of self-healing materials. Imagine a formwork that can repair itself when minor damages occur, reducing the need for frequent replacements and increasing its lifespan. Researchers are currently experimenting with incorporating microcapsules filled with healing agents into the LVL timber, which can rupture and release the healing agents when cracks or fractures appear. This innovation has the potential to revolutionize the construction industry by reducing maintenance costs and improving the overall durability of structures.

Market Trends and Predictions

The market demand for LVL timber formwork is expected to grow in the coming years. The construction industry’s shift towards sustainable and cost-effective solutions, coupled with the increasing awareness of environmental implications, favours the adoption of LVL timber formwork. As more architects, engineers, and contractors recognize the benefits of this innovative construction material, its popularity and market presence will continue to rise.

Furthermore, the integration of LVL timber formwork with Building Information Modeling (BIM) technology is another trend that is gaining traction in the industry. BIM allows for the creation of digital models that simulate the construction process, enabling better planning, coordination, and communication among project stakeholders. By incorporating LVL timber formwork into BIM models, construction professionals can optimize the formwork design, identify potential clashes or conflicts, and improve overall efficiency on-site. This integration not only saves time and resources but also enhances the accuracy and quality of the final structure.In conclusion, LVL timber formwork offers numerous advantages in terms of strength, durability, versatility, and sustainability. Its applications span across different construction sectors, providing reliable and efficient support during concrete pouring. With proper handling, storage, and on-site safety measures, LVL timber formwork can create high-quality structures while ensuring the well-being of workers. As the industry continues to innovate, the future of LVL timber formwork looks promising, offering even more advanced solutions to the construction industry’s evolving needs.

Other resources: LVL Formwork Timber